End-stage lung diseases may result in death either by oxygenation and carbon dioxide exchange insufficency or by right heart failure. The macroscopic blood oxygenator ECMO (ExtraCorporeal Membrane Oxygenation) is a therapeutic option, currently used in intensive care units, which aims to temporarily alleviate respiratory failure. Since this oxygenator need to be exchanged within 20 days because of clotting, waiting for a transplant can be critical.

The main objective of the BioArtLung project financed by the French National Research Agency (ANR -RHU) is to develop a sustainable method of respiratory assistance based on microfabrication technologies. The development of a portable, miniaturized microfluidic oxygenator that can be used for several months would add a new therapeutic solution for patients awaiting lung transplantation.

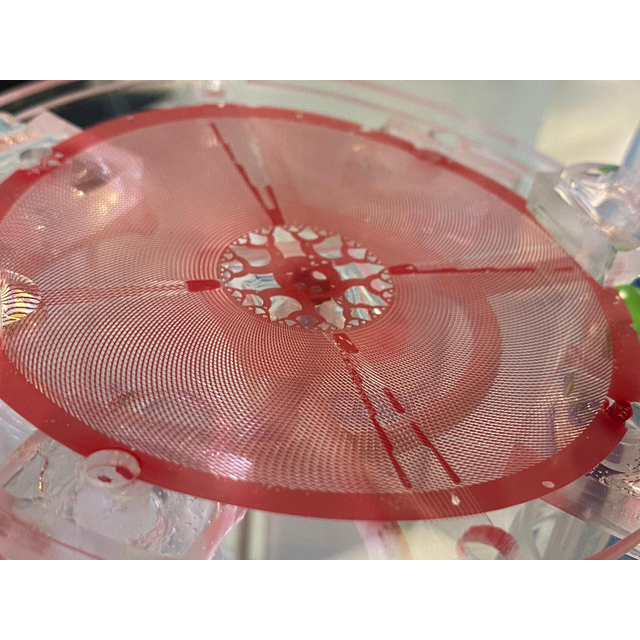

In the field of microfluidic oxygenators, maximizing gas exchange efficiency while increasing blood flow remains a major challenge, as its use on humans requires the ability to process large volumes of blood. C2N microfluidic scientists (J. Lachaux, G. Hwang et A-M. Haghiri-Gosnet) have designed a 10-centimeter diameter microfluidic oxygenator, which maximizes the gas exchange area and allows multiple levels to be stacked to improve the maximum blood flowrate. This microfluidic oxygenator is manufactured in layer-by-layer assembly based on a patented wet bonding method [hal-03318568v1]. The stacking of several trilayers allows to reach very high blood flow rates. The high performance of the stacked device in terms of blood oxygenation and decarbonation comes from the architecture designed to facilitate gas exchange, but also from the thinness of the PDMS membrane (15 microns thick), which can withstand high blood flows thanks to the optimized bonding. The geometry of the vascular network also respects the natural laws of blood vessels, allowing for reduced shear stress, promoting durable endothelialization with progenitor cells kept alive for up to 2 weeks after initial seeding.

These state-of-the-art results in terms of gas exchange efficiency and reduced priming volume have just been published in « Lab-on-a-Chip ». [A compact integrated microfluidic oxygenator with high gas exchange efficiency and compatibility for long-lasting endothelialization, Lab on a Chip, Royal Society of Chemistry, In press hal-03318488v1].

This project, coordinated by Pr. Olaf Mercier, director of the clinical research laboratory and thoracic surgeon (lung transplantation) at the Marie Lannelongue Hospital (HML), is supported by a collaboration of 5 research laboratories, including C2N, 2 INSERM laboratories (unit 1197 and 1176), 2 CEA laboratories (LITEN and LEMM) and the hydrodynamics laboratory (LadHyX). Thanks to its experience in microfluidics, C2N is a major player in the consortium for the design and study of an oxygenator adapted to medical constraints.

Contact : Julie Lachaux et Anne-Marie Haghiri

Consult the article published on Lab-on-a-chip

DOI: 10.1039/d1lc00356a

> Watch the film : Sculpter la matière - Film CNRS Images

Figure : 10 cm diameter microfluidic oxygenator with blood circulating in the vascular network