How to control the energy consumption of a cleanroom dedicated to microelectronic technologies while maintaining the environmental parameters required for micro-nanofabrication processes or materials development? This is the challenge for C2N, hosting one of the largest clean-room micro-nanotechnology facilities for academic research, which are very energy-consuming infrastructures. An analysis of the actions taken by C2N and of the prospects for reducing energy consumption, has just been published in the journal "Salles Propres“.

At the heart of C2N's research activities is a cleanroom dedicated to the manufacture of micro-nanodevices, similar to the infrastructure used for micro-nanoelectronics processes. This is the largest cleanroom dedicated to academic research in France, part of the RENATECH academic network of large-scale micro-nanofabrication facilities. The building includes a 2,900 m2 clean room, with controlled temperature, humidity and cleanliness class (ISO4 to ISO7), as well as 95 air-conditioned experimental rooms with controlled temperature and humidity, covering a surface area of 3,500 m2. More than half of C2N building's energy (~55% by 2022) is consumed by the HVAC systems. C2N's objective is therefore to reduce the impact of air-conditioning on its energy consumption, and in particular that of its cleanroom. To achieve this, a working group has been set up to carry out energy-saving actions.

Since 2021, the group has focused more specifically on the cooling and heating production systems and on the air conditioning of the cleanroom. In particular, it has optimized the operating conditions of an heat exchanger between hot water and chilled water networks, and analyzed the effect of a REDUCED mode running on some HVAC systems when the cleanroom is unoccupied. The obtained results, presented at the last ASPEC association's technical day devoted to energy performance in cleanrooms in November 2023[1] , were recently published in the journal “Salles Propres”, special issue dedicated to energy savings [2].The group demonstrated a 75% reduction of gas consumption by optimizing the heat exchanger, from 6.5 GWh in 2020 to 1.7 GWh in 2023.

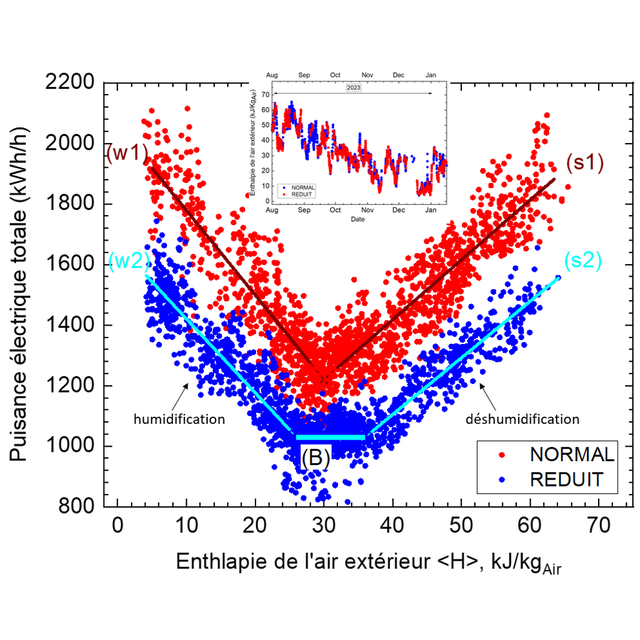

The total electricity consumed by the building was analysed and found to be directly correlated with weather conditions, and more specifically with the enthalpy of the outside air. From this analysis, the electricity savings induced by the REDUCED mode could be determined, i.e. an average reduction of 20% in the total power consumed by the building, and an annual saving of almost 1.4 GWh. The prospects for further energy savings are discussed in the article, in particular by improving the air-conditioning in the cleanroom and experimental rooms, and by extending the REDUCED mode to other HVAC systems.

Reference 1 : R. Vallin, S. Bouchoule, et A. Lemaître, « Mise en place de modes Normaux et Réduits, gains énergétiques associés et développements futurs », Journée technique de l’ASPEC - de l’air et efficacité énergétique en salle propre, Contamin@Bordeaux, 9 novembre 2023. https://www.aspec.fr/evenements/contamin-bordeaux.htm

Reference 2 : S. Bouchoule, A. Lemaître, « Etablissement de recherche - Actions de performance énergétique et retours d’expérience du Centre de

nanosciences et de nanotechnologies », dossier « Economie d’énergie : comment aller plus loin ? » , Salles Propres n°143, mars 2024. HAL : https://hal.science/hal-04556913

Figure : Total electrical power consumed by the building as a function of the specific enthalpy of the outside air, determined by measuring the temperature and relative humidity of the outside air, in NORMAL mode (red) and REDUCED mode (blue). The values are one-hour averages. The curves (s1), (s2), and (w1), (w2), are the linear regressions obtained in NORMAL and REDUCED modes, for the "summer" and "winter" periods respectively. Insert: Outdoor air enthalpy as a function of time